Key Takeaways

- Proactive is Better: A facility electrical assessment in Snohomish County is a proactive measure to uncover hidden safety risks, improve energy efficiency with SnoPUD, and ensure your building’s power systems are reliable and up to local Washington State codes.

- Local Expertise Matters: Phase3Electric is a local Snohomish County expert who understands the unique electrical challenges of our area, from aging industrial buildings to modern commercial spaces. We’re a team that answers the phone and provides clear, actionable advice.

- Beyond Code Compliance: An assessment is more than a simple inspection. It’s a comprehensive health check that identifies overloaded circuits, outdated equipment, and grounding issues, providing a strategic roadmap for maintenance and future upgrades.

- Tangible Cost Savings: By identifying energy waste, correcting power factor issues, and balancing electrical loads, a thorough assessment can lead to significant reductions in your monthly utility bills and prevent costly emergency repairs.

A thorough facility electrical assessment in Snohomish County is the single best way to uncover hidden risks, boost energy efficiency, and make sure your building’s electrical system is safe, reliable, and up to code. It’s more than just a quick look-around; it’s a detailed roadmap for keeping your critical power infrastructure in top shape.

Your Guide to Snohomish County Electrical Assessments

For facility managers and business owners, the phrase “electrical assessment” can sound a bit daunting. It often conjures up images of confusing reports, expensive fixes, and disruptive downtime. But the reality is much simpler.

Think of it as a complete physical for your building’s most critical system. This is the system that powers your entire operation, keeps your data safe, and protects everyone who walks through your doors.

At Phase3Electric, our goal for every assessment is straightforward: deliver clear, actionable insights that safeguard your investment. We’re not some giant, faceless company. We’re your reliable local Snohomish County experts who actually answer the phone. Unlike corporate competitors, Phase3Electric combines technical mastery with genuine care for our Washington community’s success. When you have a question, you’ll get an answer from someone who lives and works here.

Why Proactive Assessments Matter

Getting ahead of electrical problems is always better than reacting to them. A proactive assessment lets you spot potential issues before they turn into full-blown emergencies, helping you dodge those unexpected failures that lead to costly repairs and shut down your business.

Here’s what you stand to gain:

- Enhanced Safety: We pinpoint and fix hazards like overloaded circuits, old wiring, and improper grounding. This is fundamental to protecting your team and property from fire or electrical shock.

- Improved Reliability: A detailed evaluation uncovers weak spots in your system. This allows for smart, targeted upgrades that prevent frustrating power outages and protect your expensive equipment.

- Cost Savings: By fine-tuning your electrical system and catching energy waste, a good assessment can noticeably lower your monthly SnoPUD bills.

- Code Compliance: We make sure your facility is aligned with the current National Electrical Code (NEC) and any specific Snohomish County regulations, so you can steer clear of fines and liability headaches.

For a wider view on how these evaluations fit into the bigger picture, understanding building assessment reports offers some great context on facility-wide inspections.

Our focus, however, is squarely on the electrical systems that are the lifeblood of your operation. Through our various commercial electrical services, our mission is to give you a practical, no-nonsense strategy that keeps your business humming along safely for years.

Preparing for a Successful Electrical Assessment

A thorough and accurate facility electrical assessment in Snohomish County doesn’t just start when the electrician arrives. In my experience, the groundwork you lay beforehand makes all the difference, turning a good assessment into a great one. Getting organized ahead of time speeds things up and directly affects the quality of the final report.

Think of it like prepping for a doctor’s appointment. You wouldn’t show up without your medical history, right? It’s the same idea here. Giving your electrician a clear picture of your system’s history and current setup is crucial for a deep-dive evaluation.

This all comes down to two things: getting your paperwork together and making sure the facility is ready for a physical walkthrough. When you take these steps, you’re not just making the process more efficient—you’re showing a real commitment to safety and operational excellence.

Gathering Your Essential Documents

Before we even step on-site, one of the most helpful things a facility manager can do is pull together key documents. This file gives us invaluable context on how your system was designed, what it’s been through, and how it’s performing now. It lets us get past a surface-level glance and into the real details.

Try to compile these items:

- Past Electrical Drawings and Schematics: These are the blueprints for your entire system. They show us circuit layouts and panel locations, giving us a map to work from.

- Maintenance and Repair Records: A log of past service calls or equipment fixes can be a goldmine. It often points us directly to recurring problems or weak spots that need a closer look.

- Recent Utility Bills: A stack of your SnoPUD statements from the last 6-12 months can reveal spikes in energy use or demand charges, which are often the first signs of inefficiency.

- Equipment Manuals: For your big machinery or specialized systems, the manufacturer’s specs on power requirements are essential.

It also helps to see how electrical checks fit into the bigger picture. Reviewing a good commercial property inspection checklist can give you a better sense of how all the different systems in your building, including electrical, contribute to its overall health.

Coordinating On-Site Access and Personnel

Once your documents are in order, it’s time to think about the physical inspection. Good communication with your team is key here. You want to make sure the electrician can get everywhere they need to go safely and without causing a major disruption to your day-to-day work.

A well-prepared facility makes for a well-executed assessment. When our electricians can access key areas without delay and have historical data on hand, they can dedicate more time to in-depth analysis rather than basic fact-finding. This leads to a richer, more detailed report for the client.

The best approach is to designate one person from your staff as the main point of contact. This should be someone who knows the building inside and out and can guide the electrician. Make sure this person has keys and access to all the critical electrical infrastructure.

We’ll definitely need to get into:

- Main Electrical Rooms: Please ensure these areas are clean, well-lit, and clear of any storage or clutter.

- Server Rooms and Data Closets: It’s a good idea to chat with your IT department to schedule a time that won’t interfere with any critical network operations.

- Mechanical Rooms: We’ll need to see the systems powering your HVAC, pumps, and other large equipment.

- Rooftop Units: If you have them, we’ll need to confirm that there’s a safe way to get up to the roof.

Taking care of this prep work ahead of time creates a much smoother process for everyone. This kind of foresight doesn’t just save time—it ensures the final report is built on a solid foundation of complete and accurate information.

What to Expect During the On-Site Inspection

This is where the rubber meets the road. The on-site inspection is the hands-on part of any facility electrical assessment, where we move past the paperwork and get a real-world look at your system’s condition. The goal here is simple: see how your electrical infrastructure is actually performing day-to-day and spot potential trouble that documents alone can’t show.

For a lot of facility managers, this part can feel a bit disruptive, but it’s a critical diagnostic step. A seasoned professional knows how to work efficiently to gather all the necessary data while keeping out of your way. This isn’t just a quick walkthrough; it’s a systematic evaluation of every key component that keeps your business powered up.

A Systematic Walkthrough of Your Electrical System

We follow a logical path, usually starting right where the power enters your building and fanning out from there. It’s the best way to make sure nothing gets missed. A technician from Phase3Electric will methodically check each part of the system, from the high-voltage equipment all the way down to the outlets in your office.

This process involves a close look at a few key areas:

- Main Service Entrance and Switchgear: Think of this as the heart of your system. We’re looking for any signs of wear, corrosion, or overheating in the main breakers and conductors that feed your entire facility.

- Transformers: We’ll inspect transformers for leaks, overheating, or any unusual humming noises that can point to internal problems.

- Panelboards and Subpanels: Every panel gets opened up for a thorough inspection. We check for properly sized breakers, signs of arcing, loose connections, and clear, correct labeling.

- Grounding and Bonding Systems: We verify that your facility has a solid and effective grounding system—this is absolutely crucial for protecting both people and sensitive equipment from electrical faults.

Advanced Diagnostic Tools in Action

These days, a good assessment goes way beyond a simple visual check. We bring in specialized diagnostic tools to uncover problems that are completely invisible to the naked eye. This kind of technology lets us find and fix issues long before they can cause a catastrophic failure.

One of the most powerful tools in our kit is thermal imaging, also known as thermography. Using an infrared camera, we can literally see the heat signatures of your electrical components. Hot spots on a circuit breaker or connection are a dead giveaway of a poor connection or overloading—and we can see it long before it fails. For a manufacturing plant in Everett with heavy machinery, a quick thermal scan might reveal a motor connection that’s about to fail, preventing a costly, unscheduled production halt.

Other diagnostic tests we often run include:

- Circuit Tracing: To make sure your panel schedules are accurate and that circuits aren’t overloaded.

- Voltage and Current Measurements: To ensure your system is delivering stable power and that loads are balanced properly across phases.

- Power Quality Analysis: To catch issues like voltage sags or harmonic distortion that can wreak havoc on sensitive electronics.

This level of detailed work is exactly why professional expertise matters so much. If you’re wondering about the difference a pro makes, check out our guide on if you need a licensed electrician.

Understanding the Financial Impact

During the assessment, we’re also looking at the financial side of your electrical use. SnoPUD electricity rates and demand charges are huge factors in your facility’s operational costs.

For example, large businesses in Snohomish County that use more than 30,000 kWh a month face a base charge of $2.10 per day plus 8.365 cents per kilowatt-hour. On top of that, there’s a demand charge of $7.16 per kW for any peak consumption over the 100 kW threshold. Those demand charges can become a massive part of your bill, which makes efficiency upgrades a very smart investment.

We translate technical findings into business sense. An overloaded transformer isn’t just a technical problem; it’s a direct threat to your productivity. A poorly balanced panel isn’t just an electrical issue; it’s wasted money on your utility bill every single month.

The on-site inspection isn’t just about finding faults; it’s about building a complete picture of your system’s health. For a multi-story office building in Lynnwood, we might focus on lighting efficiency and data center power reliability. For a food processing facility in Arlington, the priority might be on wash-down-rated equipment and motor efficiency. Every facility electrical assessment in Snohomish County is tailored to the unique demands of the business it serves, ensuring our final recommendations are both practical and genuinely impactful.

Meeting Electrical Codes and Improving Safety

A proper facility electrical assessment is about so much more than just checking boxes to pass an inspection. Think of it as a proactive strategy—a way to manage risk and protect the long-term health and safety of your entire operation. At its heart, this process is all about compliance, not just with the National Electrical Code (NEC), but with the specific rules and regulations we have right here in Snohomish County, Washington.

Let’s be honest, electrical codes can feel like a labyrinth of dense, technical rules. But they all exist for one critical reason: to prevent electrical hazards that can lead to fires, expensive equipment damage, and, worst of all, serious injuries. A thorough assessment is what turns that complicated codebook into practical, real-world actions for your facility.

Common Code Issues We See in Snohomish County Buildings

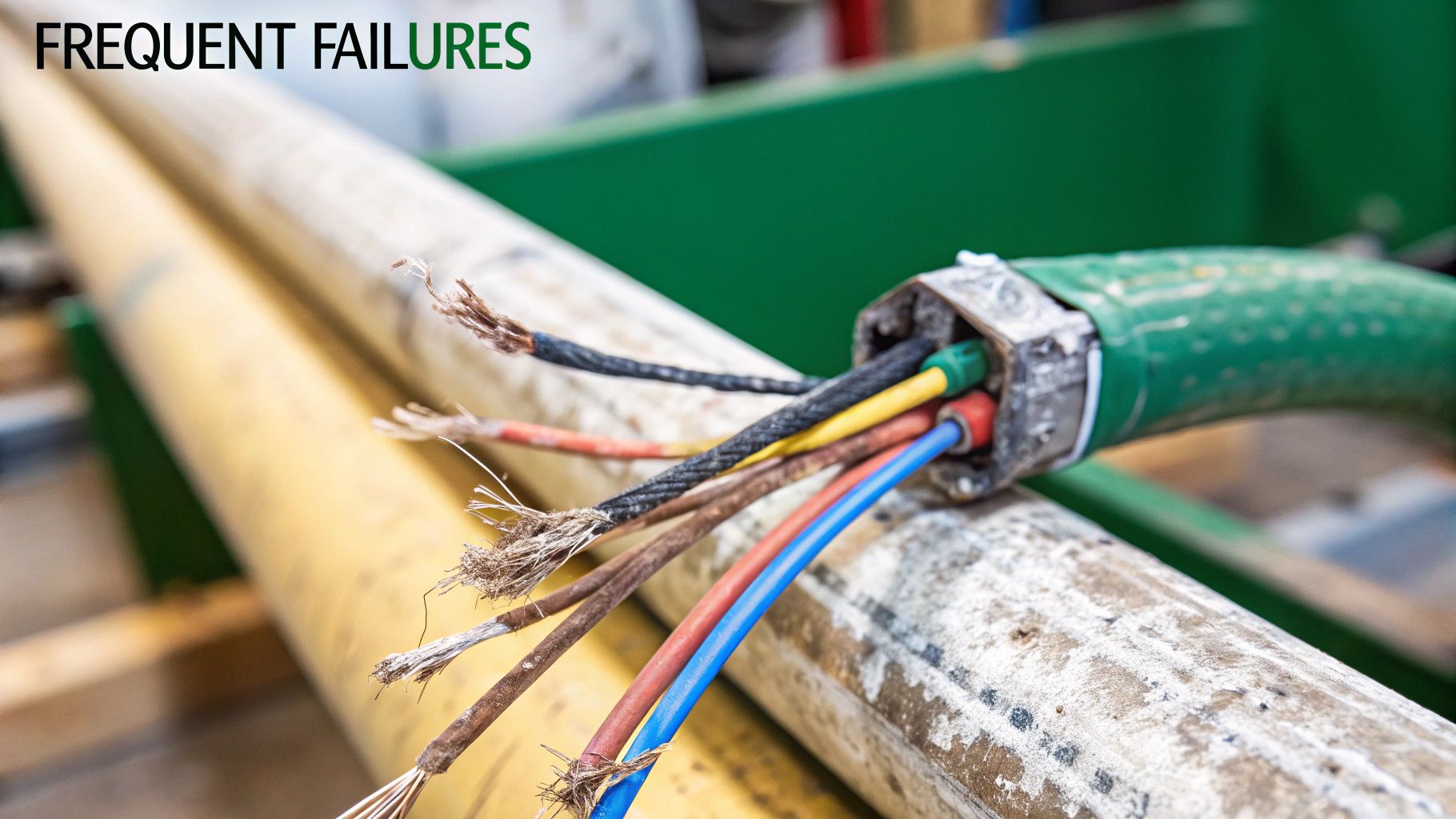

Over the years, I’ve seen the same electrical problems pop up again and again in commercial and industrial buildings across Snohomish County. While many of these issues are common in older structures that simply weren’t built for today’s power-hungry world, they can surface anywhere if routine maintenance has fallen by the wayside.

Here are a few of the most frequent violations we uncover:

- Overloaded Circuits and Panels: This is a classic, especially in older buildings you’ll find in places like Everett or Marysville. Businesses add more computers, new machinery, and modern tech, but the original circuits can’t handle the load. That’s a huge fire risk.

- Outdated Panelboards: It’s not uncommon to find panels still using old-school fuses instead of modern circuit breakers. We also find panels that are just too small for the building’s current electrical demands. These are ticking time bombs that are missing the crucial safety features of today’s equipment.

- Improper Equipment Grounding: A solid grounding system is your number one defense against electrical shock and equipment failure during a fault. We constantly find missing, loose, or corroded grounding connections, which leaves both your people and your sensitive electronics dangerously exposed.

These aren’t just minor details. An overloaded circuit is a fire waiting for a place to start. An improperly grounded machine can deliver a lethal shock. The whole point of a facility electrical assessment in Snohomish County is to find these hidden dangers before they turn into a catastrophe.

Beyond the Checklist: A True Safety Audit

Bringing your facility up to the highest safety standards is about protecting your people, your property, and your business’s future. The assessment should be viewed as a comprehensive safety audit that directly connects technical code violations to real-world business risks.

It’s a process even our local governments value. For example, in 2023, the City of Snohomish conducted its own Facility Condition Assessment (FCA) on municipal buildings to get a handle on critical systems, including electrical infrastructure. They used a scoring system to prioritize repairs and make smart investments in aging electrical systems to improve safety and reliability. You can read more about their findings in the Executive Summary. It just goes to show how even official bodies rely on these detailed assessments to manage risk.

An electrical assessment is your best tool for proactive risk management. It systematically identifies vulnerabilities and provides a clear, prioritized path to improving safety, ensuring compliance, and protecting your business continuity.

Why Local Expertise Matters

Navigating the specifics of local Washington State codes really requires local experience. Snohomish County has its own amendments and enforcement priorities that a generic, out-of-state company might completely miss. Think about the unique requirements for agricultural buildings in the Snohomish River Valley or for marine-adjacent facilities near the Puget Sound waterfront—that kind of work demands specialized knowledge.

A local expert who actually picks up the phone, like Phase3Electric, gets it. We blend a deep technical understanding of the NEC with a practical knowledge of the challenges local businesses face. We know what inspectors in our area look for and how to build solutions that are not only up to code but also make sense for your specific operation. That hands-on, community-focused approach is what turns a simple inspection into a strategic investment in your facility’s safety and resilience.

Turning Assessment Findings into an Action Plan

An electrical assessment report is more than just a stack of papers; it’s a strategic roadmap for your facility’s future. The real value of a facility electrical assessment in Snohomish County is unlocked when you turn its technical findings into a clear, prioritized action plan. This is where data becomes decisions, protecting your operations and your bottom line.

A professional report from a local expert like Phase3Electric won’t just dump a list of problems on your desk. Instead, it will carefully categorize every finding by urgency, giving you a clear path forward. This prevents that feeling of being overwhelmed and helps you allocate resources intelligently.

Prioritizing Recommendations by Urgency

The first thing to do is sort out the recommendations. A well-structured report will break everything down into clear categories, so you can easily see what needs fixing right now versus what can be planned for later.

This tiered approach usually looks something like this:

- Critical/Immediate Action: These are the red flags. Think severe safety hazards like exposed live wires, overloaded main panels, or failing grounding systems that pose an immediate risk of fire or electrocution. These issues demand attention right away, no questions asked.

- High Priority/Near-Term: These are serious problems that could lead to system failure or major downtime if you ignore them. Maybe a transformer showed signs of overheating on a thermal scan, or certain circuit breakers are tripping constantly. You’ll want to get these scheduled for repair within the next few weeks or months.

- Medium Priority/Planned Maintenance: This bucket is for things that aren’t an immediate threat but will cause headaches down the line. It could be replacing old, inefficient lighting or addressing minor code violations that affect performance but not safety.

- Low Priority/Future Upgrades: These are forward-looking recommendations focused on optimization. This might include suggestions for boosting energy efficiency, getting your system ready for future load increases, or adopting newer technologies.

Building a Compelling Business Case for Investment

With your priorities straight, the next hurdle is often getting the budget approved. This is where you have to translate the technical report into a solid business case. Instead of just showing a list of costs, you need to frame the investment in terms of return on investment (ROI) and risk mitigation.

The key is to show how these electrical upgrades will directly benefit the company’s financial health and keep things running smoothly.

An assessment action plan shouldn’t be seen as an expense; it’s a strategic investment in reliability and efficiency. Every critical issue fixed is a potential disaster averted, and every efficiency upgrade is a future cost-saving realized.

For example, when you talk to stakeholders, you can highlight things like:

- Reduced Energy Bills: Quantify the potential savings from upgrading to LED lighting or installing more efficient motors. You can even use your SnoPUD bills to show a clear “before and after” projection.

- Lower Maintenance Costs: Explain how replacing an aging panelboard now prevents a string of expensive emergency service calls later. Use your own maintenance records to drive the point home.

- Increased Reliability and Uptime: For a manufacturing facility, calculate the cost of a single hour of downtime. Frame the electrical upgrades as an insurance policy against those exact losses.

The power of acting on these findings is well-documented. For instance, back in 2010, Snohomish County undertook a major facility electrical assessment and retrofit project across 15 of its buildings. The county invested about $1.5 million in upgrades, which led to a reduction of nearly 500 tons in greenhouse gas emissions each year and saved roughly 227,600 kWh of electricity annually, proving the direct financial and environmental ROI. You can discover more about Snohomish County’s project results and see how these investments pay off.

From Report to Roadmap

Your final action plan should be a living document that lines up with your operational goals and budget cycles. If a full panel replacement is flagged as a high-priority need, your plan should detail every step for that project. For guidance on that specific process, you can learn more about how to upgrade an electrical panel in our detailed article.

Beyond immediate safety fixes, a good assessment can also highlight opportunities for future energy upgrades. For facilities looking to explore solar panel integration, understanding the basics can be a valuable first step. This kind of forward-thinking approach turns a simple assessment into a long-term strategy for a safer, more efficient, and more resilient facility.

Got Questions About Electrical Assessments? We’ve Got Answers.

If you’re thinking about a facility electrical assessment in Snohomish County, you probably have a few questions. That’s a good thing. Understanding what you’re getting into is the first step toward making a smart decision for your property. We get these questions all the time from facility managers and business owners, so let’s clear up some of the most common ones.

My aim here is to give you straight answers so you can feel confident about protecting your building, your people, and your business operations.

How Often Should I Get My Facility Assessed?

This is easily the most common question I hear. For most commercial buildings, a comprehensive electrical assessment every 3 to 5 years is a solid rule of thumb. It’s frequent enough to stay ahead of equipment aging, catch up with new code requirements, and adapt to any changes in how you use your space.

Now, that’s just a baseline. Some situations call for a closer look, more often. If you’re running heavy-duty machinery around the clock, have a data center on-site, or your building has seen a few decades, you’ll want to be more proactive. For these higher-risk facilities, I often recommend an annual thermal imaging scan to spot hotspots before they turn into full-blown failures.

And there are a few specific triggers that should always prompt an immediate assessment:

- Right after you’ve completed a major renovation or built an addition.

- Anytime you’re bringing in significant new electrical loads, like a new production line.

- If you’re seeing nagging problems like breakers that keep tripping or lights that flicker for no apparent reason.

Ultimately, we can help you figure out a schedule that makes sense for your specific building and how you use it.

Isn’t an Assessment Just a Fancy Word for an Inspection?

Not at all. They’re two completely different beasts, and it’s a critical distinction. A standard electrical inspection is essentially a pass/fail checkup. It’s designed to confirm that your system meets the bare minimum safety codes at a specific moment in time—usually because a permit or a property sale requires it.

An electrical assessment goes so much deeper. Think of it less like a simple checkup and more like a complete physical for your electrical system. We’re not just looking for code violations. We’re hunting for performance bottlenecks, hidden inefficiencies, and subtle signs of wear and tear that could become major points of failure down the road. A standard inspection would fly right past these issues.

An inspection tells you if you’re compliant right now. An assessment gives you a strategic roadmap for keeping your facility safe, reliable, and efficient for years to come.

The real value is in the final report, which gives you a prioritized list of actionable recommendations to improve safety, eliminate potential downtime, and even cut your energy costs. It’s a long-term plan, not a one-time snapshot.

Can This Really Lower My SnoPUD Bill?

Absolutely. In fact, cutting your SnoPUD energy bill is one of the biggest and most immediate returns you’ll see from a proper assessment. We’re specifically looking for the quiet energy vampires that are often responsible for inflating your monthly costs.

For instance, a detailed assessment will uncover things like:

- Imbalanced Electrical Loads: When one phase of your system is working much harder than the others, everything becomes less efficient and you’re paying for wasted energy.

- Outdated Gear: Old lighting, motors, and HVAC components are notorious energy hogs compared to modern, efficient alternatives.

- Poor Power Factor: This is a technical issue that can actually cause your utility to penalize you with extra charges on your bill.

We don’t just find the problems; we give you the solutions. Your report will include specific, data-backed recommendations—like a plan to retrofit with high-efficiency LED lighting, install variable frequency drives (VFDs) on your large motors, or make corrections to fix that power factor. Tackling these issues can lead to a serious drop in your monthly energy use and a much friendlier bill from SnoPUD.

Ready to get a clear picture of your facility’s electrical health? The team at Phase3Electric has been helping businesses across Snohomish County do just that for years. We deliver detailed facility electrical assessments with clear, actionable insights to protect your investment.

Schedule Your Facility Electrical Assessment with Phase3Electric Today